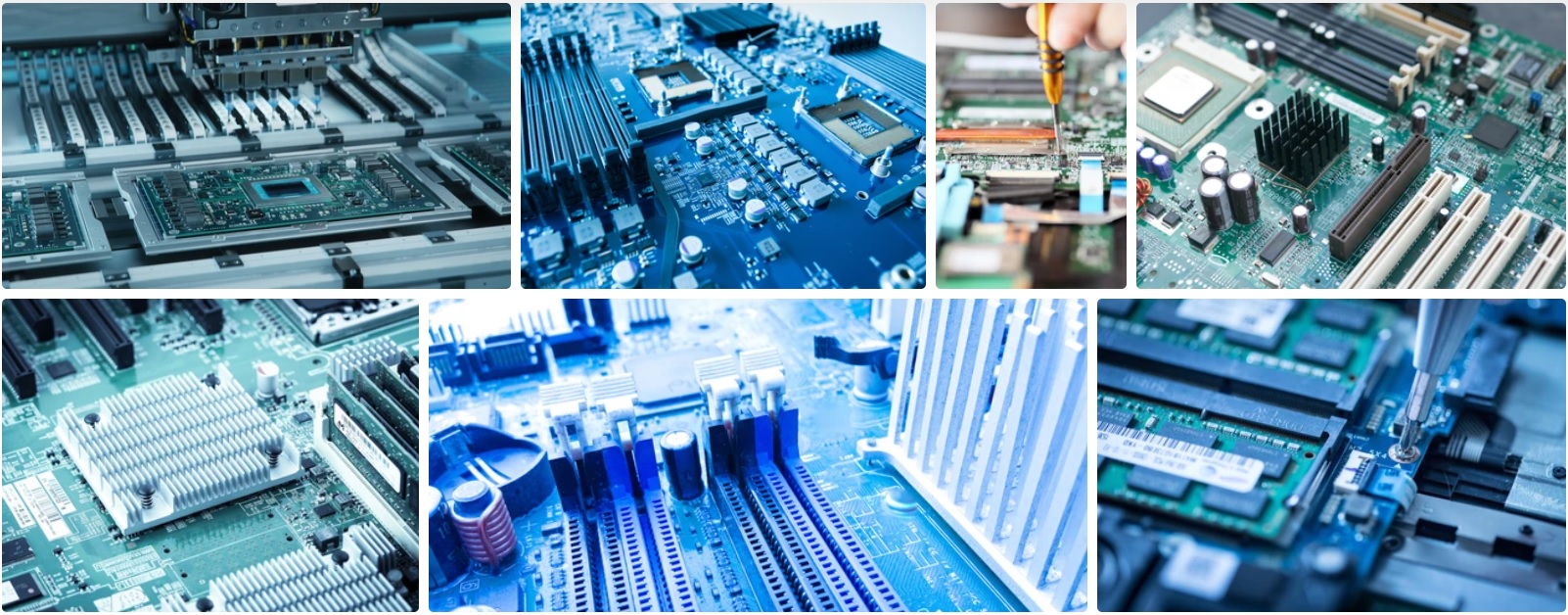

Circuit board assembly / printed circuit board assembly is the abbreviation of printed circuit board assembly, that is, the production process of printed circuit board circuit board or PCBA after SMT assembly or DIP plug-in process.

Circuit board assembly/ Printed circuit board assembly usually refers to a process, and can also be understood as a finished circuit board, that is, circuit board assembly can only be completed on a printed circuit board. A printed circuit board refers to an empty printed circuit without parts board. The above is the difference between printed circuit board and circuit board assembly.

SMT and DIP are methods of integrating components onto circuit boards. The main difference is that SMT does not require holes to be drilled in the PCB, but in dip, it requires pins to be inserted into the drilled holes.

SMT (surface mounted technology) mainly uses a placement machine to install some micro and small parts on the circuit board. Its production process includes PCB positioning, solder paste printing, mounting machine mounting, reflow oven, and inspection.

DIP is a "plug-in", that is, a part inserted into a printed circuit board board. It is a plug-in integrated part when some parts are large in size and not suitable for the installation process. The main production processes are back glue, plug-in, inspection, wave soldering, board brushing, and finished product inspection.

You should be able to clearly distinguish what is a printed circuit board now, right? What is Circuit Board Assembly? Circuit board assembly can basically be considered a finished product, as some factories will produce printed circuit board assemblies for shipment, such as computer motherboards sold separately. A printed circuit board can only be considered as one component. The circuit board is an important part of the entire printed circuit board assembly, but it cannot represent the printed circuit board assembly. Because parts such as ICs, resistors, capacitors, inductors, connectors, etc. must be soldered on the PCB to become a finished product, the PCB should only be considered as one part.